Easy Positioning, Plug & Play

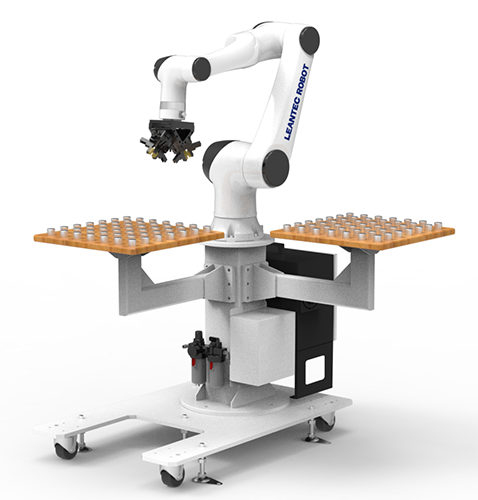

Traditional industrial robots face challenges such as complex operation, diverse specifications, and difficult integration. This is especially true in an era where customized demands are increasingly prevalent, and processing is no longer limited to large quantities of single workpieces. As a result, customers require equipment with higher automation deployment efficiency and flexibility, capable of quickly switching materials and production lines to meet diverse manufacturing needs. To address these pain points, Leantec has introduced the modular “Leanloader” and “Industry Process Package,” enabling robots to achieve true “plug-and-play” functionality.

The integration of industrial robots with mobile material carts as modular units allows for rapid deployment without the need for additional hardware installation, effectively meeting various production requirements. The software process package simplifies industry-specific technologies into easily operable modules. Users can simply select the appropriate module based on their needs to complete robot adaptation, eliminating the need for complex manual setups. This modular solution significantly enhances production efficiency, making automation applications more flexible and scalable.

Advantages of Using Leantec’s “Plug & Play” Robot Solution

Leantec Solutions

Hardware

Scenarios

- Leantec’s Leanloader is engineered to drive flexible, automated production for small-batch, multi-variety metal machining. Designed for quick deployment with minimal setup, this solution offers a fast and efficient path to automation, perfectly suited for industries with diverse and dynamic production needs.

- Specializing in metal industry applications such as material handling, machine tending, and measurement/inspection, Leantec’s mobile cart goes beyond just providing robotic arms. This fully integrated ecosystem includes smart grippers, intelligent pallets, production traceability, and data collection, delivering a complete, intelligent solution that enhances productivity and operational flexibility.

| Features | Problem | Solution & Benefits |

| Quick Installation | Traditional robotic arms typically require the installation of fixed anchors or heavy-duty bases to secure the arm, resulting in high installation costs. This setup restricts the arm’s mobility, limiting the flexibility of the factory’s spatial configuration. | Leanloader is equipped with locking casters and a mounting bracket, allowing the robotic arm to be securely positioned with a single wrench. No heavy-duty lifting equipment, such as overhead cranes or hoists is required, a single operator is able to complete the installation. This “plug-and-play” system offers rapid deployment. When the production line needs reconfiguration, simply loosening the mounting bracket allows the leanloader to be moved to the next work station, providing flexibility for dynamic production setups. |

| Quick Connection | When setting up the signal handshake between the robotic arm and the machine tool, the process of complex wiring, defining various handshake signals, and testing communication often results in significantly high setup costs. | When integrating with the Syntec machine tool system, communication is achieved seamlessly using a single Ethernet cable. For third-party systems, I/O connectors enable direct signal handshaking, paired with the connection package for plug-and-play functionality. This approach drastically reduces configuration time and minimizes setup costs, ensuring quick and efficient integration. |

| Smart Pallet and Fast Changevoer | Robotic machine tending requires physical pallets to hold workpieces. Traditionally, customers face the burden of additional costs for custom designing, wiring, and manufacturing these pallets to meet specific needs. | ● Leanloader features dual-layer/rotary pallets, control buttons, and an enclosed safety barrier that isolates personnel from the robot, ensuring safe material handling during operations. ● The software, combined with the pallet process package, simplifies setup by only requiring communication signal testing and teaching pick-and-place points, cutting down setup time and accelerating production deployment. ● Easily adjust pallet station sizes based on production plans to accommodate various workpieces and meet dynamic production line needs. ● The optional flipping table module enables automatic rotation of workpieces for two-sided machining in one-to-two or one-to-many tool machine handling processes. |

Leanloader Modular Solution

Dual-Layer Leanloader

- Compatible Workpieces: Various types of machined components, round bars, standard rotational bodies, and parts with angular positioning features.

- Applicable Industries: Lathe machining, CNC machining centers, drilling and tapping machining, grinding machine, and more

Rotary Leanloader

- Compatible Workpieces: Various types of machined components, round bars, standard rotational bodies, and parts with angular positioning features.

- Applicable Industries: Lathe machining, CNC machining centers, drilling and tapping machining, grinding machines, and more

Collaborative Robot Leanloader

- No fences required, enabling seamless human-robot collaboration.

Software

Leanloader Machine Tending Solution

One-on-One

One-to-Two

One-to-Three

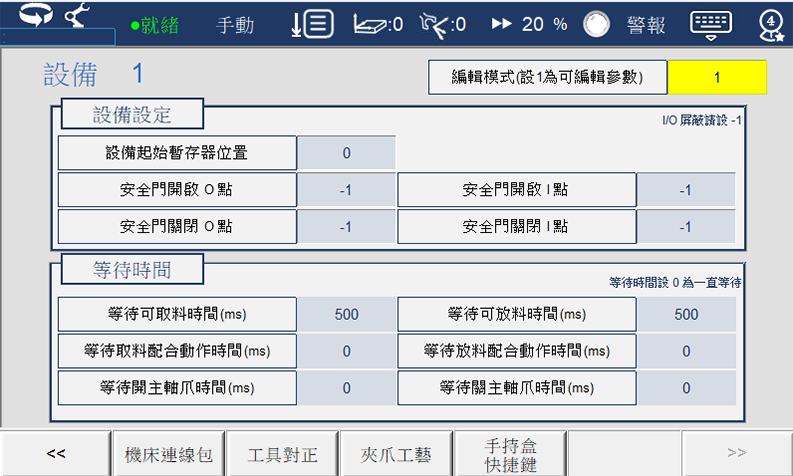

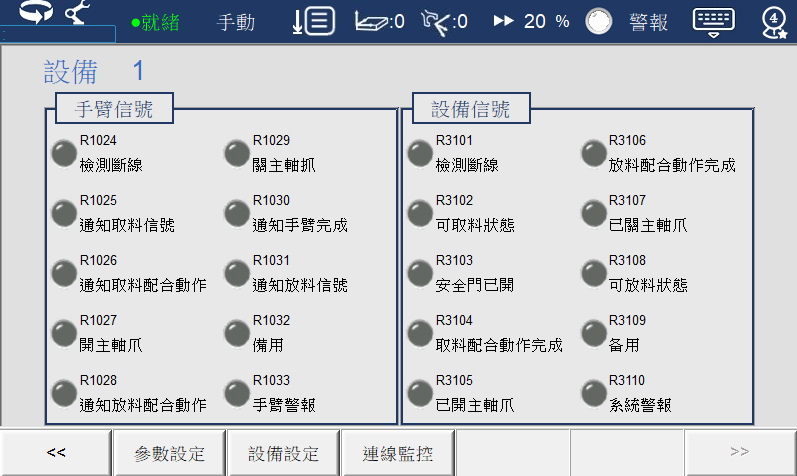

Machine Connection Package

Tool Alignment Package

Tray Pallet Package

Gripper Package

Smart Reversal Package

Problem Statement

- Traditional CNC machines and robots struggle with complex and time-consuming connection processes, making signal integration and task coordination a challenge.

Solution & Benefits

- The “Machine Tool Connection Package” streamlines and simplifies the connection between robots and CNC machines, turning the setup process into a plug-and-play experience. With just one Ethernet cable, users can instantly establish a connection without the need for complex configurations. Task coordination is done through an intuitive, dialogue-based interface—eliminating the need to manually define complicated parameters. This significantly accelerates equipment integration, reducing setup time and getting production up and running faster. Additionally, the package includes a user-friendly monitoring interface, enabling real-time status tracking for seamless operation.

Connection Package Setup Screen

Connection Package Status Monitoring Screen

Problem Statement

- Traditionally, aligning the robot and CNC machine spindle’s workpiece clamping point has been a manual process, relying on visual judgment. This not only consumes significant time but is also highly inconvenient and prone to errors, making the process difficult to execute accurately.

Solution & Benefits

- The “Tool Alignment Package” simplifies this by allowing users to teach the CNC machine spindle’s surrounding three points. The system then automatically and precisely calculates the spindle’s center point. This eliminates tedious manual steps, streamlining the alignment process and drastically improving the speed and efficiency of robot point teaching and alignment tasks.

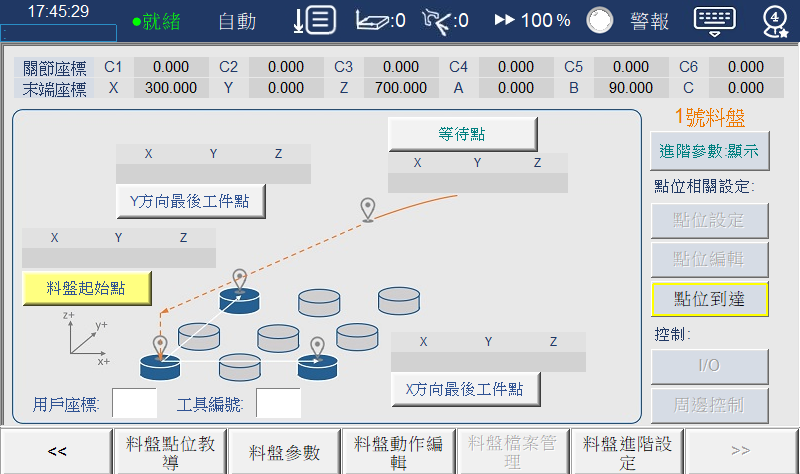

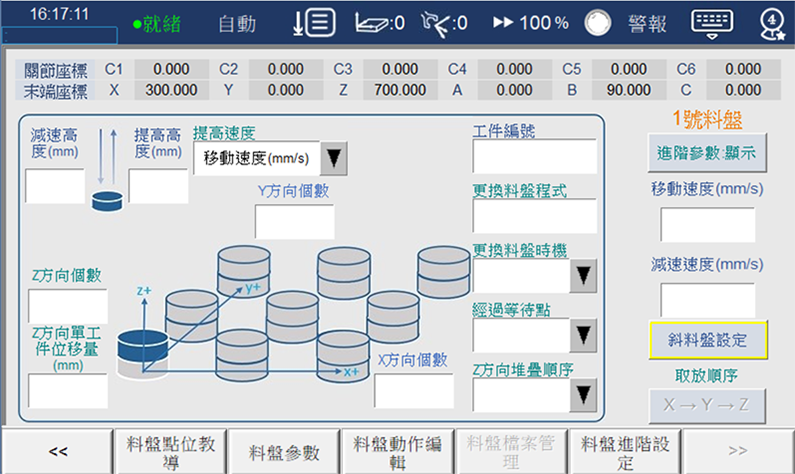

Problem Statement

- Trays used to hold workpieces typically have regularly repeating point positions. Manually teaching these numerous repetitive points can be an extremely time-consuming and monotonous task for operators.

Solution & Benefits

- With the “Tray Pallet Package,” customers only need to teach 3 points and set a few simple parameters. The software automatically calculates and generates the remaining points, significantly enhancing teaching efficiency. The system also provides motion parameters, allowing different robot actions to be performed during tray handling, such as wait timers or controlling the gripper’s open/close actions. Additionally, it supports applications with not only flat trays but also 3D and tilted trays.

Three-Point Tray Coordinate Teaching

Supports Inclined Tray Applications

Supports 3D Tray Applications

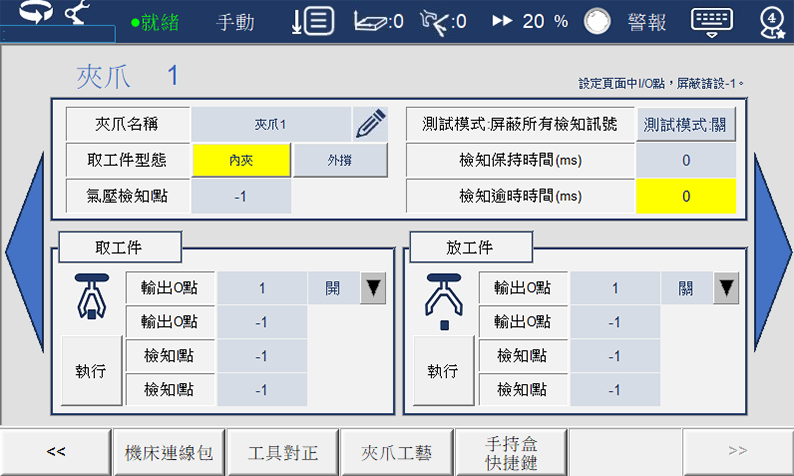

Problem Statement

- Gripper control requires manual wiring of physical IO signals. After setting up the connections, customers must define the gripper control settings in the software, a process that is both time-consuming and cumbersome.

Solution & Benefits

- The “Gripper Package” streamlines this process by allowing customers to easily configure grippers and their corresponding IO signals through an intuitive interface. It supports multiple gripper configurations, including inward clamping and outward spreading. These settings can be switched instantly without system restarts, ensuring seamless transitions and operational efficiency.

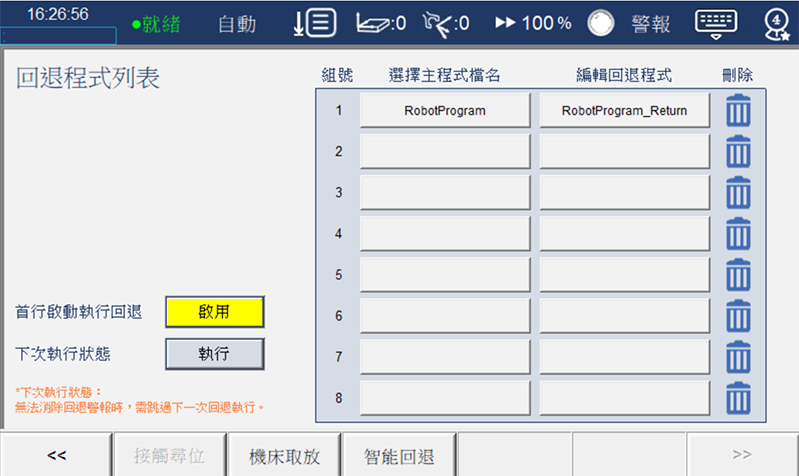

Problem Statement

- In environments with obstacles or within machine tools, robot interruptions can make manual repositioning difficult. Operators often struggle to move the robot back to a safe location. There’s a need for a one-touch solution that allows the robot to automatically return to a predefined safe point, ensuring both ease of operation and safety.

Solution & Benefits

- The “Smart Reversal Package” simplifies this by utilizing pre-set safe paths. With a single button press, operators can trigger the robot’s automatic return. The robot autonomously detects its interruption point and safely navigates back to its safe position. This process reduces manual intervention, minimizes collision risks, and ensures enhanced operator safety.

Reversal Program Settings List

Conversational-Based Reversal Settings Interface

Related Products

LXC100-906R

Dual Layer Leanloader

LXC11P-1468C

Dual Layer Leanloader

LXC11P-1717C

Dual Layer Leanloader

LXC200-1206R

Rotary Leanloader

LC800-5

Collaborative Robot Arm