One Machine, One Arm – Smart Manufacturing

In conventional CNC machining, the loading and unloading of workpieces is manually performed by operators. As automation demands increase, manufacturers are seeking to replace manual labor with robotic arms. However, when customers purchase a CNC machine and subsequently install a robotic arm, they often encounter additional costs for equipment testing and automation tuning. Moreover, considerable time is required to ensure seamless integration between the robotic arm and the CNC system, which not only increases the complexity of the production process but also extends the timeline for automation deployment. To address these challenges, Leantec introduce an integrated automation solution: “One Machine, One Arm”.

The core concept of “One Machine, One Arm” is to directly integrate the robotic arm into the CNC machine during the manufacturing phase, thereby making the robotic arm a core component of the CNC system. This design minimizes the need for separate installation and testing processes, significantly reducing the cost and time required for automation integration. By purchasing a single, fully integrated system, businesses eliminate the need to source and synchronize separate robotic arms and CNC machines. All required components are pre-integrated at the factory, allowing for faster deployment of automated production lines and enhanced operational efficiency.

The “One Machine, One Arm” solution delivers a fully integrated, turnkey automation system, providing customers with a streamlined solution that meets all their automation requirements in a single package. We believe this approach represents the future direction of the industry, offering customers a cost-effective, high-efficiency automation deployment solution.

Advantages of Leantec’s One Machine One Arm Solution

Leantec Solutions

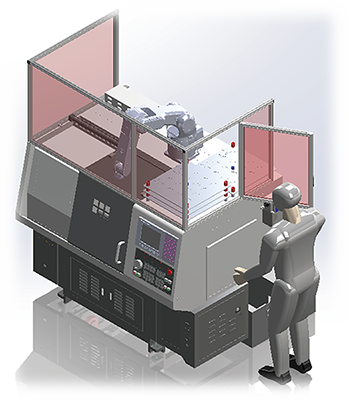

One Machine One Arm Concept

Hardware Architecture

Robot Monitoring Module on CNC

Robot Control Module for CNC in the Grinding Machine Industry

- For CNC manufacturers (hereafter referred to as machinery makers), incorporating Leantec’s robotic arms during CNC machine assembly positions these arms as a standard feature in the machining industry, significantly enhancing the overall value of CNC machines. This shift transforms the CNC machine from a traditional processing tool into an intelligent, automated loading and unloading system. For end-user processing factory, the equipment they acquire from machinery makers will evolve from a standalone CNC machine to a comprehensive solution that integrates both manufacturing and automation.

- Leantec brings deep expertise and technical proficiency to the “One machine, One arm” solution, offering full support to machinery makers. Our extensive product range of robotic arms is paired with expert recommendations tailored to each customer’s specific machine requirements. Prior to assembly, we validate the solution’s feasibility through detailed simulation and analysis, ensuring compatibility and preventing potential issues such as misalignment or improper fit post-installation. This proactive approach effectively minimizes the risk of operational inefficiencies and cost overruns for our customers.

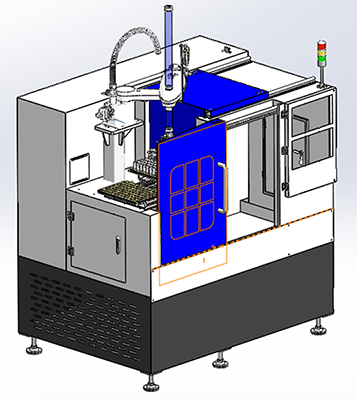

Articulated Robot Mounted on Machine Tool

4-Joint Robot Mounted on Machine Tool

Problem Statement

- In conventional CNC machining setups, robotic arms are typically retrofitted after the machine’s delivery. This non-“One Machine, One Arm” architecture requires operators to interface separately with the CNC system and the robotic arm controller, increasing operational complexity. The independence of the two systems results in a higher learning curve and complicates signal interaction between the CNC and the robotic arm, which in turn escalates maintenance and calibration challenges.

Benefits

- Leantec’s “One Machine, One Arm” solution directly addresses these issues by enabling a fully integrated hardware and software environment. Rather than a simple retrofitting of the robotic arm, this solution ensures that the robotic arm’s control module is embedded within the CNC’s operating system. This allows for centralized monitoring of the robotic arm’s status, direct point teaching, and editing of robotic arm programs through the CNC interface, streamlining operations and reducing complexity.

- Furthermore, Leantec provides a position teaching device specifically designed to interface with the CNC control system. This device replicates the familiar manual wheel operation, minimizing the learning curve and enabling rapid configuration of the robotic arm’s positions, ensuring that operators can quickly adapt to and manage the integrated system.

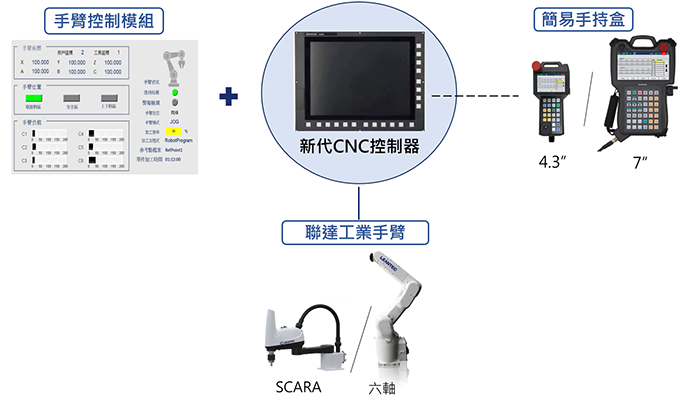

One Machine, One Arm Solution Architecture

- CNC Controller + Handheld Pendant for Direct Control of Leantec Industrial Robot

- The robotic arm integrates directly with the CNC machine, eliminating the need for a separate electrical cabinet. It can be wired and powered alongside the CNC, reducing both cost and space requirements.

- CNC + ROBOT Hardware and Software Integration

- Operate the robotic arm via G/M CODE commands, offering an intuitive and user-friendly interface.

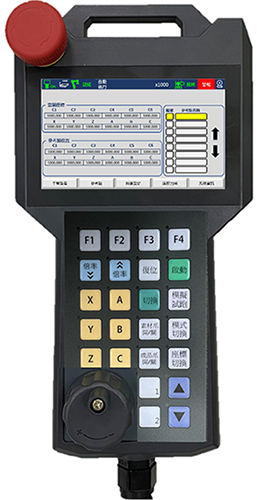

- Optional Handheld Pendant/MPG Wheel for Enhanced Control

- Cost and Space Optimization

- Simplified Architecture: Robotic arm is pre-installed as standard feature.

CNC Controller with Integrated Arm Control Module

- Robot Status

- Machine Program

- Reference Point

- Matrix Pallet

Compact Handheld Box with 4.3″ / 7″ Display

- Point Teaching

- Status Monitoring

- Remote Tool Compensation

- Hot Swappable

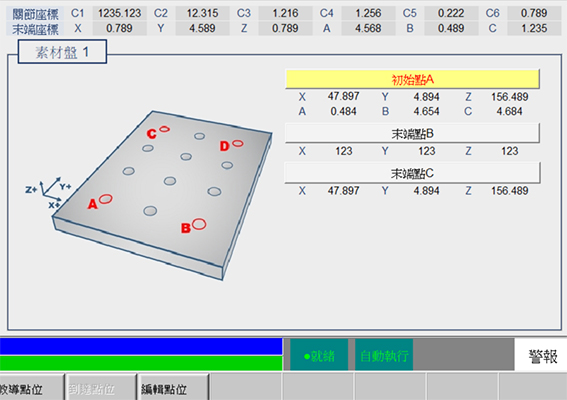

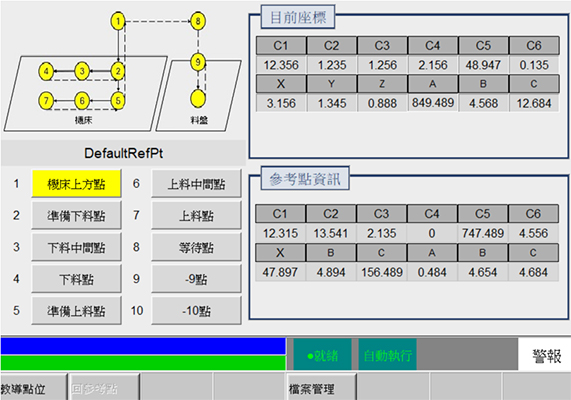

- Robot Monitoring Module

Enables real-time monitoring of the robotic arm’s status, speed settings, current coordinates, I/O signals, workpieces count, and the name of the active program. This provides operators with comprehensive visibility into the robot’s performance, enhancing operational efficiency. - Robot Reference Point Teaching Function

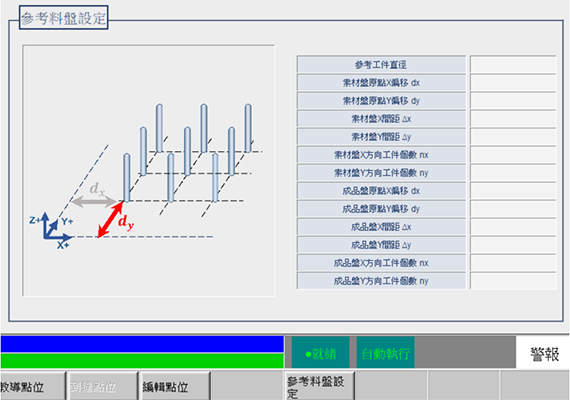

The system records and displays frequently used movement paths of the robotic arm within the CNC environment, enabling quick and intuitive point teaching. Reference point names are clearly defined to improve user comprehension, reducing the learning curve and accelerating the integration process. - Pallet Module

Before machining, workpieces must be placed on pallets, which often require teaching numerous points. By implementing the pallet module feature, the number of points that need to be taught is reduced to just three, significantly lowering the cost and time associated with automation setup and fine-tuning.

Robotic Arm Status Monitoring

Tray Workflow

Reference Point Setting

Problem Statement

- Grinding machines are essential for CNC tool grinding, a specialized segment within the grinding machine industry. The industry is known for rapid processing cycles, short machining times per workpiece, and frequent loading/unloading. As a result, replacing manual labor with robotic arms delivers significant efficiency gains, with automation becoming a critical need across the sector.

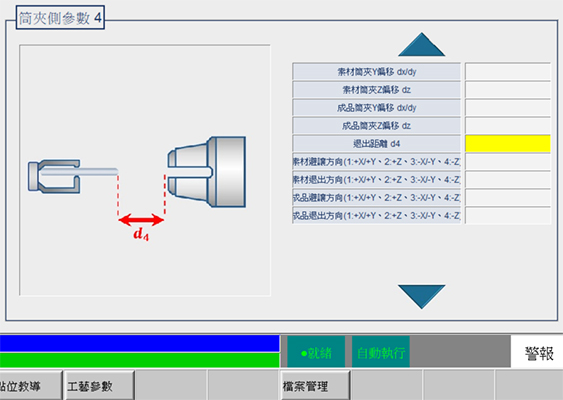

- Tool grinding involves a wide range of workpieces, and high frequency in changing machining types. When switching between different tools, the varying lengths and radii of the workpieces require adjustments to the robotic arm’s movement paths. This means the arm’s positions must be re-taught, driving up the cost of automation adjustments.

Benefits

- For the highly automated tool grinding industry, robotic arms have become a must-have feature for machines. Leantec’s “One Machine, One Arm” solution is the perfect fit for this need with numerous success story within the industry. By integrating robotic arm control directly into CNC software, we help users drastically reduce the time and cost involved in learning how to operate the arm.

- Leantec’s “One Machine, One Arm” solution also provides a specialized industry process package for tool grinding machines. When users change workpieces, instead of manually re-teaching the arm’s points, they simply input key parameters such as workpiece quantity and size. The system automatically recalculates and updates the arm’s point data, slashing setup and adjustment costs and streamlining the entire process.

Tool Grinder Process Package Interface

Tool Grinder Process Package Interface

Related Products

LA580-4H

Reach: 580mm

Payload: 4kg

LA580-4H

LA707-7H

Reach: 707mm

Payload: 7kg

LA707-7H

Reach: 906mm

Payload: 7kg

LA906-7

LS400-3

Reach: 400mm

Payload: 3kg

LS400-3

LS600-6

Reach: 600mm

Payload: 6kg

LS600-6