Smart Vision for Pick & Place, Smarter Manufacturing

In modern manufacturing, robotic arms are crucial for boosting production efficiency and slashing labor costs. However, traditional robotic handling still faces significant challenges, such as high precision requirements, limited flexibility, and a lack of adaptability to changing conditions. Conventional systems rely on fixed paths and preset parameters, which struggle to meet the fast-paced, ever-changing needs of production lines. For example, when dealing with scattered materials, operators must manually place each workpiece onto dedicated pallets, wasting time, labor, and adding unnecessary complexity.

To tackle these challenges, integrating vision technology with robotic arms has proven to be a game-changing solution. By leveraging 2D or 3D vision, robotic arms can capture and analyze workpiece data in real time—eliminating the need for custom pallets and manual intervention. This significantly streamlines the entire production process. Additionally, vision-guided alignment drastically speeds up production line adjustments. While traditional systems require re-teaching and verification during robotic arm changes, causing downtime of over a day, vision technology reduces this to just one hour, dramatically improving efficiency. By enhancing robotic arm performance, vision technology makes production lines more flexible and agile, helping the manufacturing industry move toward greater automation, intelligence, and responsiveness.

Advantages of Using Leantec Solutions

Leantec Solutions

3D Bin Picking

Vision Pallet Handling

Workpiece Reference Point Calibration

Problem Statement

Traditional robotic arm handling requires operators to manually place workpieces on designed fixtures before the arm can pick them up using pre-programmed postures. This creates unnecessary complexity and depends heavily on fixed paths and preset parameters, making the robotic arm rigid and unable to adapt to the dynamic and varied demands of the production line.

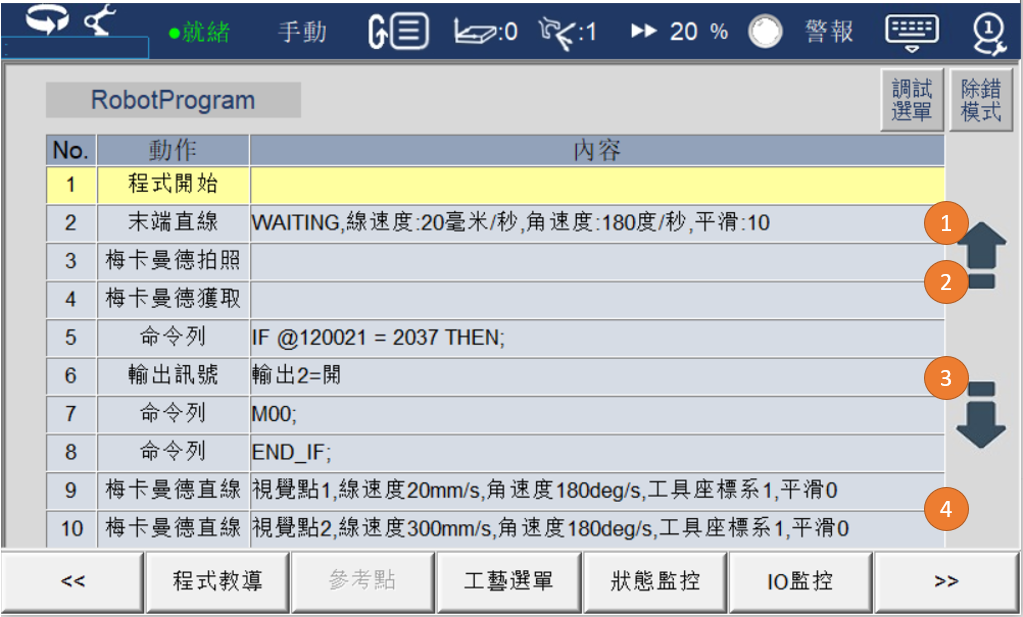

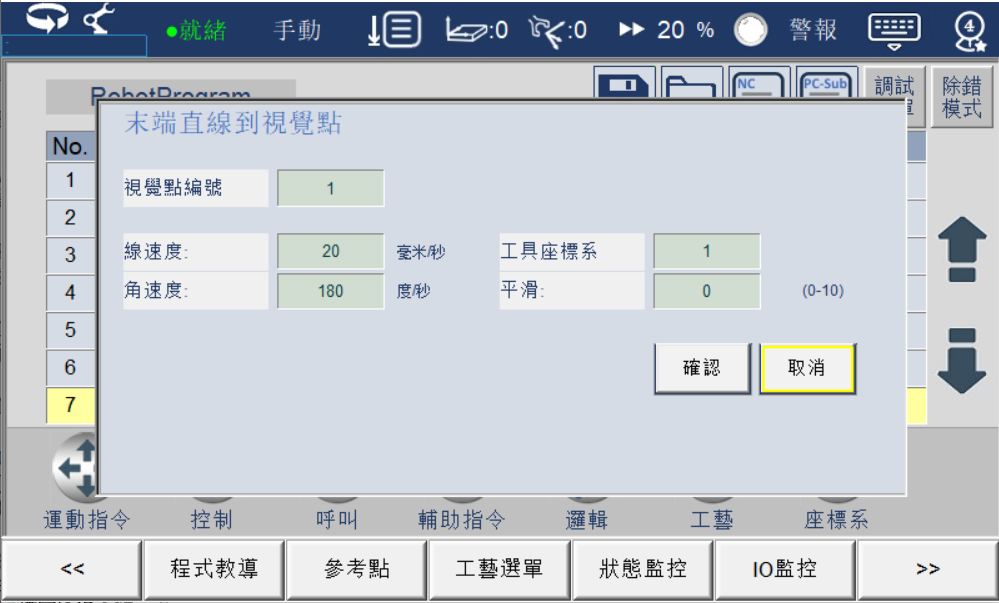

Process Package Overview

- This process package uses Mechmind’s vision recognition system to instantly detect the position and posture of workpieces and send this data to Leantec’s robotic arm for seamless handling. This provides a complete solution for tool loading and unloading—no need to sort incoming materials.

- With modular vision-based handling, users can easily select and insert the required vision functions directly into their machining programs. The intuitive interface ensures quick, hassle-free setup, enabling users to swiftly configure vision-guided handling tasks.

3D Bin Picking

Vision Pick and Place Module

Vision Pick and Place Module

Problem Statement

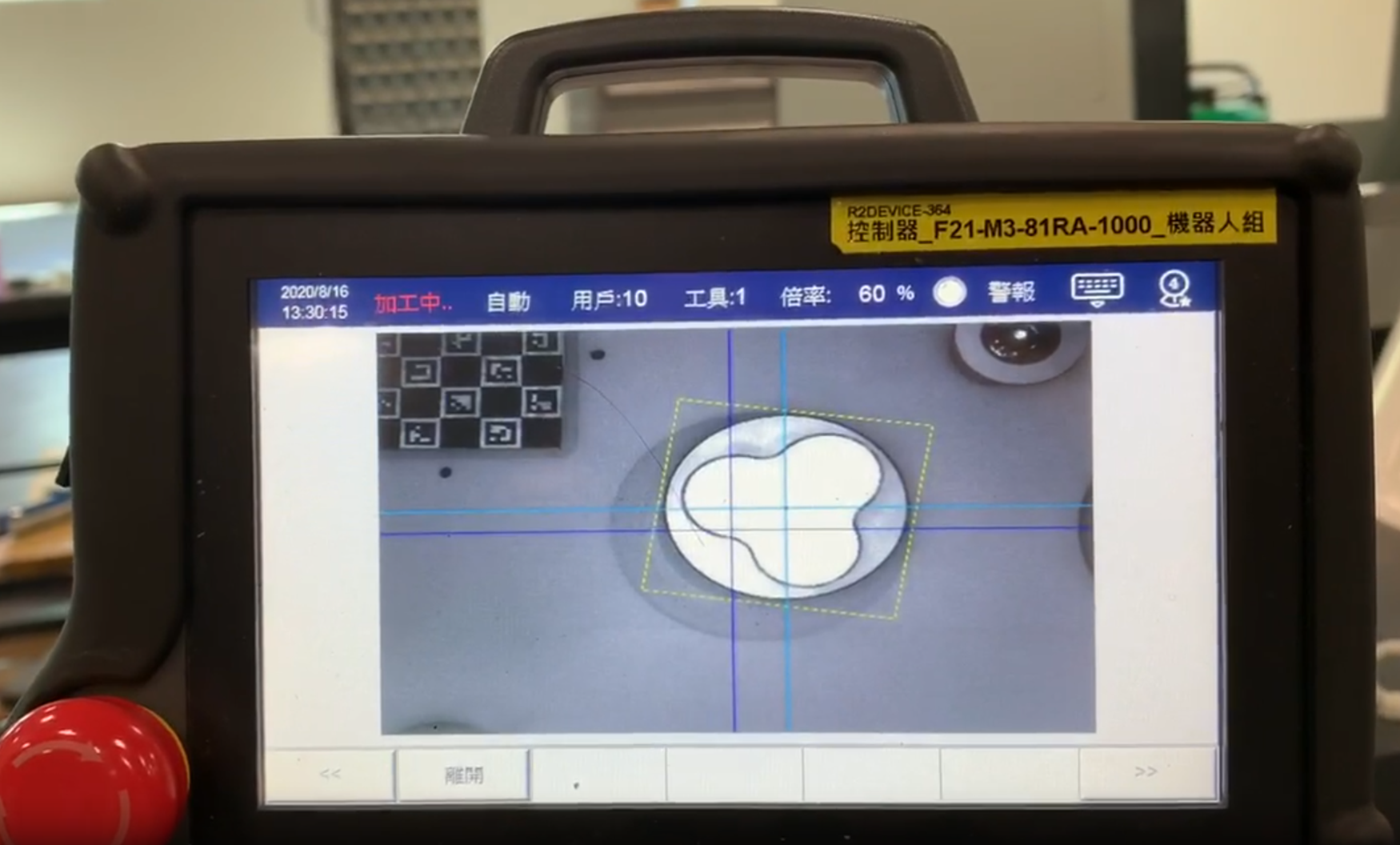

Factories often rely on pallets to supply materials to robotic arms. However, when pallet positioning is off, the arm and workpieces become misaligned. This requires precise alignment and parameter adjustments every time the pallet is changed, creating inefficiencies, especially in environments with frequent pallet changes.

Process Package Overview

This process package uses vision recognition to automatically detect both the pallet and workpiece positions, removing the need for time-consuming pallet re-setting and boosting pick-up accuracy. By leveraging ArUco data on the pallet, it quickly identifies the workpiece type and calculates any offset, enabling real-time corrections. Before each pick-up, the robotic arm uses vision to accurately position itself, ensuring precise handling of misaligned workpieces.

Vision Pallet Handling

Vision Workpiece Status Monitoring

Vision Workpiece Status Monitoring

Problem Statement

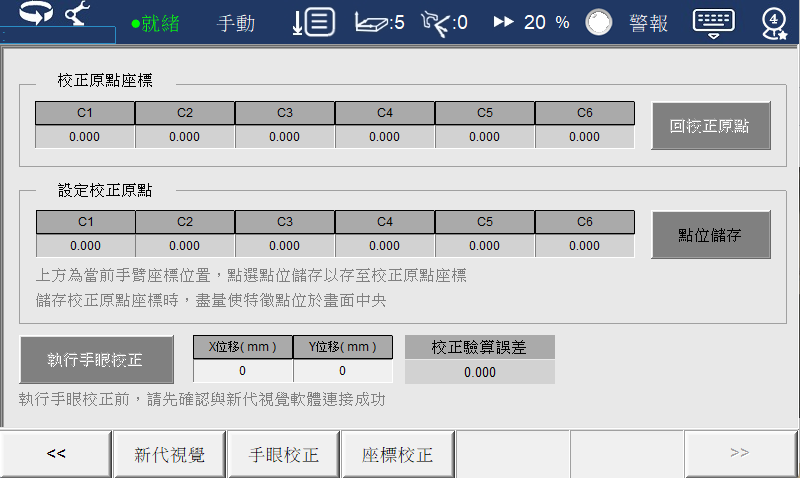

Robotic arms frequently need to switch production workpieces based on orders or schedules. Each change shifts reference points, making previously programmed positions obsolete. This is particularly problematic in applications with multiple machining points, wasting time and resources as new point data has to be rebuilt.

Process Package Overview

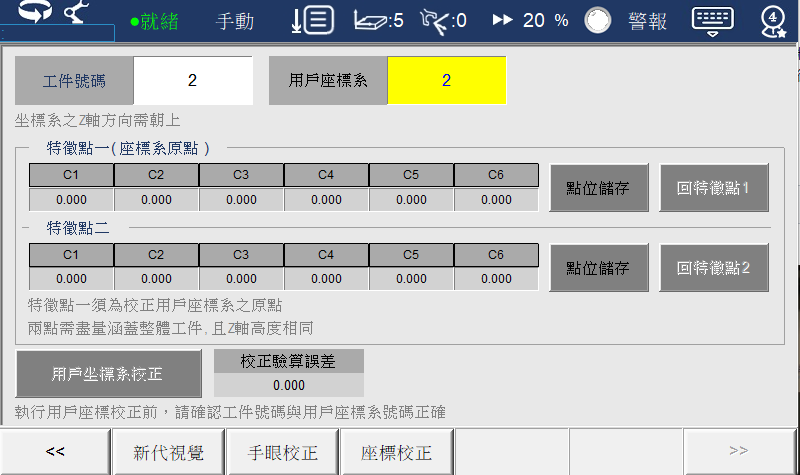

- This process package streamlines reference point calibration with just a single click, automatically recalibrating the points. Once calibrated after a line change, the system automatically adjusts the reference points, so there’s no need for further adjustments during production—keeping the process flowing smoothly without slowing down operations.

- The package can store up to 20 workpiece configurations, each with customizable recognition features, giving you the flexibility to meet a variety of needs and ensuring a tailored solution for every application.

Workpiece Reference Point Calibration

One-Click Reference Point Calibration

One-Click Reference Point Calibration

Compatible with Leantec’s Full Range of Robotic Arms

R Series

High Precision

Featuring a high IP rating and compact design, this series offers excellent repeatability and space efficiency—ideal for pick-and-place in precision machining. The hollow wrist design reduces cable entanglement, making it perfect for tasks like pick-and-place, polishing, and assembly.

C Series

High Payload

This high-payload series is optimized for pick-and-place and welding, offering a cost-effective solution that lowers automation barriers. Compatible with Syntec control systems and application packages, it streamlines smart factory integration.

H Series

Collaborative Robot

This high-protection, lightweight collaborative robot is easy to install and space-efficient. With drag-to-teach and compatibility with Leantec’s mobile carts, it enables safe, flexible human-robot collaboration.

Y Series

SCARA

Leantec SCARA robots offer high precision, durability, and cost-efficiency. The IP54 model ensures reliable performance in harsh environments, making it ideal for pick-and-place and assembly in the 3C industry.