SynMaster Smart Manufacturing –

Achieving Cost Reduction and Efficiency

A one-stop solution to meet customers’ needs for building intelligent factories.

Automation often faces challenges such as equipment diversity, inconsistent communication protocols, operational confusion, and the absence of a unified control system. These issues result in high integration complexity and costs, which act as significant barriers to automation adoption. The complexity and high expense of integrating robotic automation often cause businesses to hesitate in moving forward.

SynMaster is the solution designed to address these challenges. As a “Centralized Control Software,” it seamlessly integrates various equipment, simplifies communication interfaces, and reduces integration costs. With features such as remote tool compensation and automated process management, SynMaster effectively eliminates the common pain points of automation.

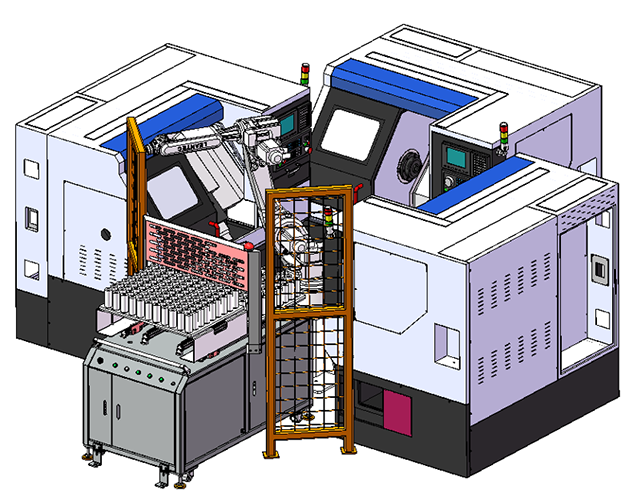

Leantec drives the “Processing Unit” concept, integrating equipment into a unified system to provide a complete solution that helps clients achieve automation at the lowest cost while improving machining quality and uptime. With SynMaster, businesses can achieve higher production efficiency and intelligent management, optimize workflows, and embrace the future of smart manufacturing.

Advantages of Using Leantec Solutions

Leantec Solutions

Leantec offers SynMaster, a highly adaptable platform designed to meet a wide range of customer needs. With its modular design, the standard version can be easily expanded by integrating additional functional modules, allowing customers to tailor their automation units efficiently. It’s like building automation with building blocks—flexible, scalable, and perfectly suited to diverse requirements.

Standard Version

Remote Tool Compensation Module

Tool Compensation & SPC Module

High-Mix Low-Volume Process Management Module

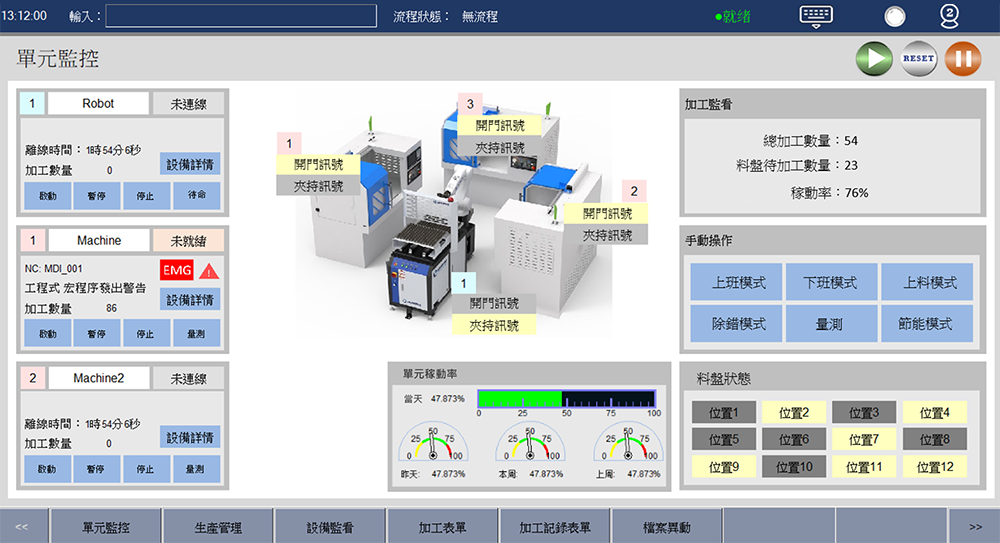

SynMaster Overview

- SynMaster seamlessly integrates with cloud-based systems to enable smart, value-added functionalities, while also linking with various machines to streamline control. Serving as the central control hub, much like a car’s dashboard, it offers a unified interface to manage all devices in the unit, simplifying operations.

- The system is versatile and can be deployed on both Syntec automation controllers which provide comprehensive support for axis control and I/O management and standard Windows-based industrial PCs. This flexibility allows customers to select the most suitable hardware for their needs, optimizing their automation process without being tied to specific devices.

- Key features of the basic version include: Equipment status display, alarm monitoring, remote start/stop functions, resource value read/write capabilities and file transfers for processing etc.

- SynMaster’s interface is fully customizable to meet various operational needs, allowing users to add: equipment overview, factory renderings, utilization rate tracking. This flexibility ensures that SynMaster can be tailored to meet specific management requirements, driving higher efficiency and enhanced operational control.

SynMaster Product Architecture

Customizable Homepage & Utilization Monitoring

Remote Equipment Monitoring

Manual Equipment File Transfer Configuration

Problem Statement

- While the widespread use of industrial robots has significantly improved factory productivity, it has also introduced operational challenges. To ensure operator safety, safety enclosures are typically installed around robots, preventing direct access to machines for tasks like data adjustments (e.g., tool compensation). This limitation can negatively affect the accuracy of machining operations, impacting product quality and dimensional consistency.

Solution and Benefits

- The SynMaster Remote Tool Compensation Module empowers operators to modify machine data directly from outside the safety enclosure, without interrupting robotic operations or opening barriers. This capability allows tool compensation to be done remotely, leading to higher uptime and improved machining precision, all while maintaining a safe working environment.

- SynMaster also supports integration with measurement instruments. By combining measurement data with remote tool compensation functionality, it enables automatic tool compensation on machines without operator intervention, achieving a fully unmanned production line. This automation minimizes human error, optimizes precision, and ensures consistent, high-quality output across production cycles.

No need to interrupt production or enter the safety enclosure;

external tool compensation enhances operational efficiency.

Operators can manually adjust the remote tool compensation table.

By integrating measurement instruments,

SynMaster automatically runs tool compensation.

Supports multi-axis machines from different brands.

Problem Statement

- Is the “Remote Tool Compensation Module” not advanced enough? Operators need a more efficient and automated tool compensation process, with intelligent management and analysis of compensation history to ensure consistent quality.

Solution and Benefits

- The SynMaster “Process Tool Compensation and SPC Module” enhances the functionality of the Remote Tool Compensation Module. It shifts from manual entry of “compensation values” to automatic input of “measurement values,” streamlining the compensation process. SynMaster automatically calculates compensation results, eliminating the need for manual calculations and reducing operator training costs.

- Additionally, the SPC functionality records tool compensation data, transforming it into actionable insights. It calculates and analyzes CPK (Process Capability Index), a key performance indicator of process stability and accuracy. By utilizing CPK, users can more effectively manage quality, significantly improving the consistency and reliability of the manufacturing process.

Advanced Process Tool Compensation, automates compensation calculations

and simplifies operator tasks.

Historical Data Management, tracks and analyzes compensation history

for superior quality control.

Problem Statement

- In traditional machining environments, most workpieces typically use the same CNC machining file. However, with the rise of customized production, each product design can be unique. In small-batch, multi-variety production scenarios, different workpieces require different machining files. In the past, factories relied on manual transmission and switching of machine programs, which not only required heavy manual intervention but also failed to achieve full automation.

Solution and Benefits

- The SynMaster process management module first offers a pallet management function, allowing each workpiece to be assigned specific machining programs and processes corresponding to different machines. It also features automatic file transfer, enabling integration with dispatch systems or CAD/CAM software to automatically upload the generated machining files to the machines. Finally, through a series of intuitive process teaching instructions, users can convert traditional manual processes into fully automated solutions.

Small-batch, multi-variety production with flexible pallet process configurations.

Conversational teaching instructions for easy management of machining processes.

SynMaster Connects Seamlessly with Leantec’s Full Range of Robotic Arms

R Series

High Precision

Featuring a high IP rating and compact design, this series offers excellent repeatability and space efficiency—ideal for pick-and-place in precision machining. The hollow wrist design reduces cable entanglement, making it perfect for tasks like pick-and-place, polishing, and assembly.

C Series

High Payload

This high-payload series is optimized for pick-and-place and welding, offering a cost-effective solution that lowers automation barriers. Compatible with Syntec control systems and application packages, it streamlines smart factory integration.

H Series

Collaborative Robot

This high-protection, lightweight collaborative robot is easy to install and space-efficient. With drag-to-teach and compatibility with Leantec’s mobile carts, it enables safe, flexible human-robot collaboration.

Y Series

SCARA

Leantec SCARA robots offer high precision, durability, and cost-efficiency. The IP54 model ensures reliable performance in harsh environments, making it ideal for pick-and-place and assembly in the 3C industry.